For the Love of Radiant - Page 2

|

|

|

|

|

|

|

|

|

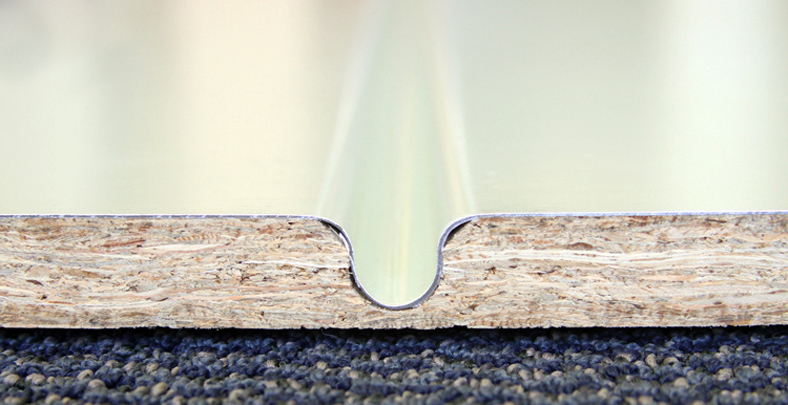

"High-mass concrete cannot easily be nailed to, of course," said McCord, citing one of Warmboard's selling points over its competition. "This limits flooring options to glue-down hardwood, and other radiant panels are often too thin to hold the nail adequately.

"Because of this," he continued, "these panels require an additional layer [or two] of plywood to cover the panel. This increases floor heights, hides the tubing during installation (making a tubing hit more likely), and places additional obstacles between the heat in the tube and the interior of the home."

Of course, floor heights are raised by Warmboard as well, necessitating some adaptation.

"Warmboard-R, which is the product most appropriate for renovating an Eichler, is 13/16" thick," states McCord. "Regular doors can have the bottom shaved down. Baseboards may need to be moved. This depends on existing flooring however. If a home [already] has a layer of plywood over the concrete, floor heights and sliding doors would be minimally impacted."

One Eichler Network technician said these needs should not be minimized when considering radiant products.

"One major problem in an Eichler is the sliding doors are very low to the concrete," says John Owens of John Owens Services in San Rafael. In a recent email interview, Owens added, "If a panel system is installed with a finish floor above, you would have to step up as you enter the sliding doors."

Still, savings from the superior conductivity of Warmboard panels just may be worth the trouble.

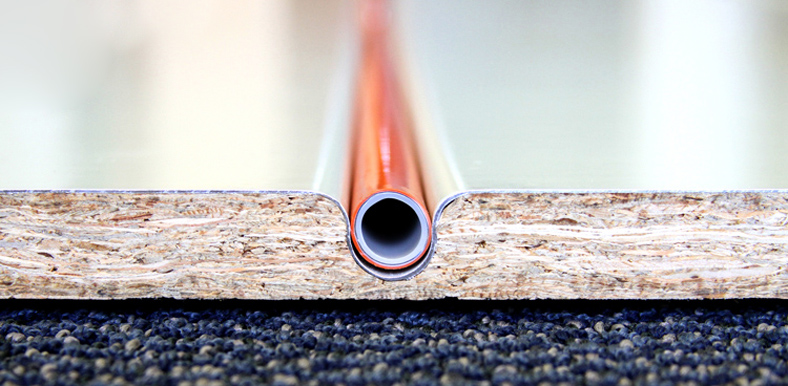

"Hydronic radiant heat functions by pumping water through a tubing beneath the floor," McCord explains. Other radiant methods are primarily focused on covering up that tubing [with concrete] or creating a level surface (wood panels with tubing channels).

"Warmboard panels, however, are coated with thick aluminum, an excellent conductor which helps to rapidly 'pull' the heat from the water and transfer across the surface of the floor. So, our panels respond much more quickly to heating needs. Alternatively, because Warmboard is so much more conductive, you can use much lower temperatures. Most systems require water temps in the 120 to 140 degree range, while Warmboard generally runs between 90 and 110 degrees."

Time marches on—with Eichler's original radiant systems now 50 to nearly 70 years old. "A lot of the plumbing in these Eichlers has aged, and it's getting increasingly common that these systems are failing," warns McCord. While the key to continue to maintain the health of your original system is regular inspections and tune-ups, keep in mind, when it comes to leak repair, copper tubing can readily be repaired but steel-tube repair is risky with follow-up leaks common, most technicians agree.

When Eichler owners find themselves in need of replacing their failed radiant systems, there's a handful of limited replacement options: Pex-based new in-slab radiant system, mini-split systems, baseboards, rooftop systems—and, of course, new above-slab radiant systems such as Warmboard.

For many, system failure will accompany a very important decision: What will be my new system of choice? McCord, of course, would like you to consider his rather than give up on radiant heat. "Warmboard provides a way to maintain the look of the Eichler while experiencing improved comfort and energy efficiency," he says.

• All six of the Eichler Network's Bay Area radiant heat maintenance companies have been added to Warmboard's installer network.