Your Eichler's Mahogany Paneling - Page 3

Eichler owner and general contractor Henry Calvert of Calvert Ventures, Inc. has seen many Eichler interior walls go through changes. "By the time I come into a job, the customer usually has already decided what they want to do with their paneling. Oftentimes we are moving walls, and owners may decide to use sheet rock, since it brightens up the home and is smart from a fire-safety perspective. Others want us to restore their original paneling."

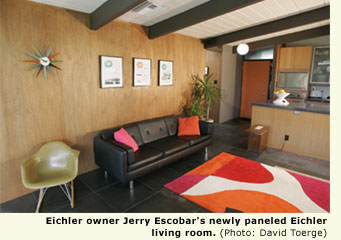

Escobar devised a plan for bringing back the original feel of the home. He decided that since the living room was the central room in the house, he would put new wood paneling there. He also decided to line one wall of the hallway and one in the master bedroom.

There were challenges involved as Escobar set about to create his new paneled walls. First, he found that the paneling selection at local lumberyards had great variation in color and grain from one sheet to the next. To get around this, Escobar carefully selected each sheet, ensuring consistency and quality. "I even lined them up side-by-side in my backyard to select panels that would give me a matching grain and the appearance of one continuous piece of wood," says Escobar. "Since I was planning to stain them, I chose the lightest pieces I could find and ones without any knots or blemishes."

Tips for Fire SafetyMost building codes today prohibit the use of wood paneling as a stand-alone material for interior walls because of fire safety issues. Eichler owners looking to reduce their risk can do so by introducing drywall to their interior walls. For those who want to maintain their original paneling look, consider installing paneling over new sheet rock. This provides the best of both worlds: greater fire safety and code compliance, while protecting the original Eichler aesthetic. But fire safety does not stop there. Many of the wood oils and solvents used to clean and treat paneling are also flammable in their liquid state, so extreme caution should be used when working with these materials. As a rule, maintain adequate ventilation, do not work near sources of flames, and be sure to clean brushes and rags when work is complete. |

Calvert and his painting associate, Ray Moseley, owner of RPM Painting &Decorating in Redwood City, are currently in the midst of a restoration project. "For this job, we are completely removing the finish and starting over," points out Moseley. He uses a chemical stripping method to remove the existing finish, which allows him to start over and to make the wood look like new. According to Moseley, chemical stripping is faster and cheaper than replacing the paneling. He prefers Citrus-Strip chloride stripper, an environmentally friendly product.

After the stripping, Moseley works with the client to select a stain color, which could be based on matching the original color, or some variation of it. He applies the stain, and then puts a coat of matte-finish polyurethane over it. "I like polyurethane because it helps to protect the stain," says Moesley. "Kids can use color crayons on it, and it will wash right off. If you use the matt finish, it looks like the original but lasts much longer."

Jerry Escobar used a slightly different approach to prepare and stain his newly purchased paneling. He suggests the following steps: Check for roughness, and smooth with 1000-grit sandpaper, being careful not to affect the wood veneer; wipe dust off with a dry cloth; apply a wood conditioner (he prefers Minwax) to seal the wood and allow it to absorb the stain evenly; apply the stain with a Terri cloth 'staining pad'; rub off excess and let dry; apply stain in the direction of the grain.

Minwax and other brands of stain come in a variety of colors, including natural and mahogany. Escobar mixed his own color, using a combination of the two options, and testing it until he got the exact appearance he was looking for. Also, keep in mind that the color will look different once dry and in different light settings. Be sure to preview test strips in the location where the paneling will ultimately be installed.

When Jim Herold's Sunnyvale Eichler burned to the ground seven years ago, he was determined to rebuild his home with many of the same specifications of the original home. As part of his painstaking process, Herold chose several walls in the common living areas to serve as focal points, and decided to use wood paneling to face those walls. To ensure compliance with code, he installed his paneling over a sheet rock base.

Herold, however, was not satisfied with the quality of available mahogany paneling, so he had some custom made by Belmont-based Jordan International Company. Herold chose Anigre, an African hardwood. Jordan also custom milled Herold's quarter-rounds. This milling process was expensive, costing nearly $200 per sheet at the time.