Roof Insulation

In December 1955, Eichler owner Bob Johnson paid only $12 to heat his home. Back then, original Eichler roofs had less than an inch of fiberglass, flattened under a heavy load of tarpaper and thick gravel.

For many occupants, this small amount of insulation wasn't enough; inside, candles were known to melt in the summer heat, and steamy breath fogged the air on cold winter mornings.

Utility bills are much higher now, even after inflation is taken into account, but fortunately technology has become available over the years to help Eichler owners save money. Thanks to improved ceiling insulation, an Eichler can be transformed from the least comfortable summer or winter residence to a haven of energy-efficient comfort, and a quiet one as well.

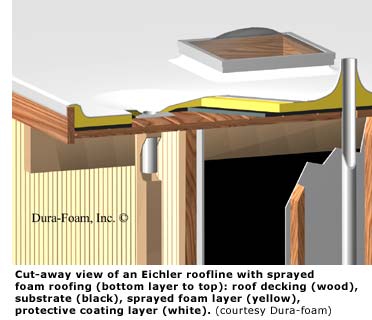

Roofing systems, including tar and gravel, sprayed foam, torch-down, and single-ply, now use two forms of the same generic polyurethane foam roof insulation material. As an insulator, polyurethane foam, whether 'board-stock' or 'sprayed,' has been transforming Eichlers for three decades. Insulation must be installed when re-roofing, not as an afterthought.

Most insulation materials—fiberglass, cellulose, and rock wool are common examples—rely on trapped air to slow temperature changes. The level of effectiveness dramatically improved when polyurethane foam became available. A cubic inch of poly foam has approximately one million tiny cells. Board foam traps air better than fiberglass and is a better insulator.

However, sprayed foam has an a 20 percent higher R-value than board foam of the same thickness. The cells of sprayed foam are closed, trapping an inert gas that insulates better than any material available today. Those cells also enable spray foam to be used to waterproof. To understand R-value, first consider that one inch of wood equals R-1. Thus, an R-19 roof assembly will behave thermally as though the ceiling was made only of wood that is 19 inches thick. R-19 is a good target for any Bay Area Eichler. This can save 25 to 40 percent on heating costs over a poorly insulated roof.

Installing insulation on Eichler roofs beyond R-19 may not be practical. Occupants may not notice any added insulation benefit, and the additional cost could take decades to recoup. Generally, an insulated tar or torch-down roof is comparable in cost to a sprayed foam roof. An insulated single-ply roof is usually the most expensive.

On a roof, reflecting heat is good, absorbing heat is not. The newest version of the California energy law called Title 24 will soon require changes in most roof systems, and in fact require reflective roof coating on most new roof installations beginning October 2005. For now, low-rise homes, which would include most Eichlers, are excluded from this energy-saving requirement. Sprayed foam roofing already surpasses the Cool Roof and Energy Star requirements, which have become desirable industry benchmarks.

For example, on a 90 degree summer day, a non-reflective Eichler roof surface can reach 160 degrees. Board insulation must prevent this extreme heat from getting inside by keeping it in the roof assembly. Heat builds up and cooks the roof system, shortening service life. On the other hand, the white reflective surface of a foam roof only reaches 110 degrees on the same day. This 50 degree difference makes insulating the Eichler much easier. Spray foam has the unique ability to insulate on the very outside layer, and avoid undesirable 'heat-sinks' (gravel) or 'short circuits' (fasteners).

When placed on the outside of the building envelope, the first one inch of sprayed foam is able to achieve 80 to 90 percent of the insulating effect. (As a side note, the space shuttle uses one inch of uncoated spray foam to insulation its large, brown stainless-steel fuel tank that is 300 degrees below zero.)

Foam boards are factory made in four-by-eight foot panels in various thicknesses. They are fastened to the wood using long nails with large square heads, long screws, or sometimes even adhesives. Boards should be well secured, especially to avoid problems since it's possible for their size to change with age (typically they shrink) up to four percent. A tar, single-ply, or torch-down roofing membrane is then installed on top.

Foam boards insulate well, but one recent study has shown that a rooftop foam board assembly can lose up to 25 percent of its effective insulation value because air can move in the gaps at the electrical and around board edges. Foam boards insulate better when their edges are taped, and multiple board layers are more effective when the top layers are installed in a staggered fashion over the ones below. This layering is seldom carried out, since it could add considerable expense for labor and material to the installation for the same R-value of insulation.