For the Love of Radiant

|

|

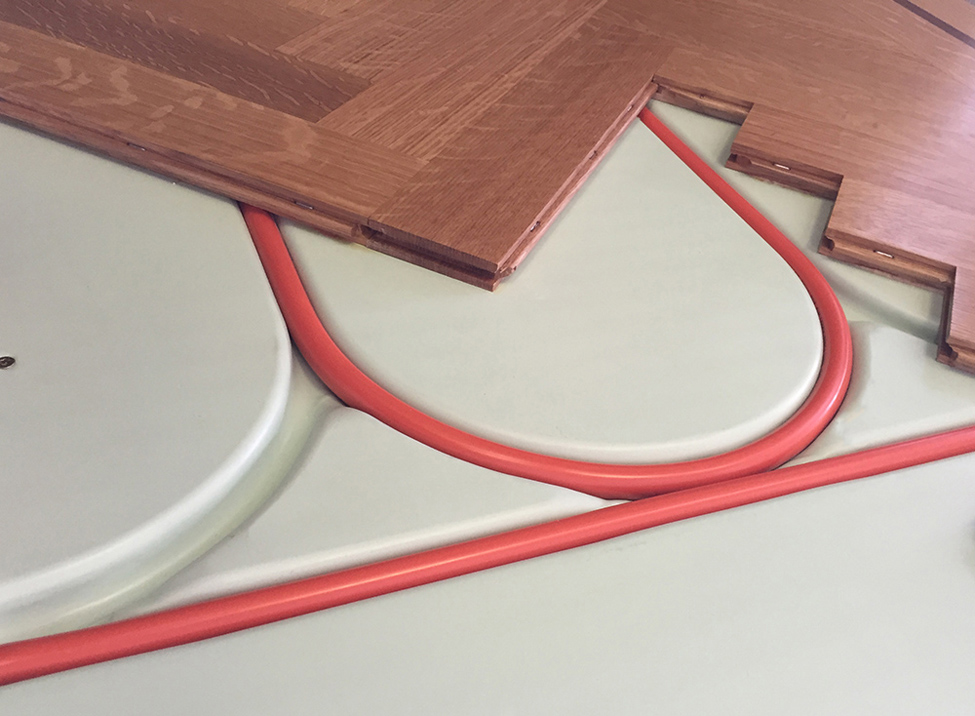

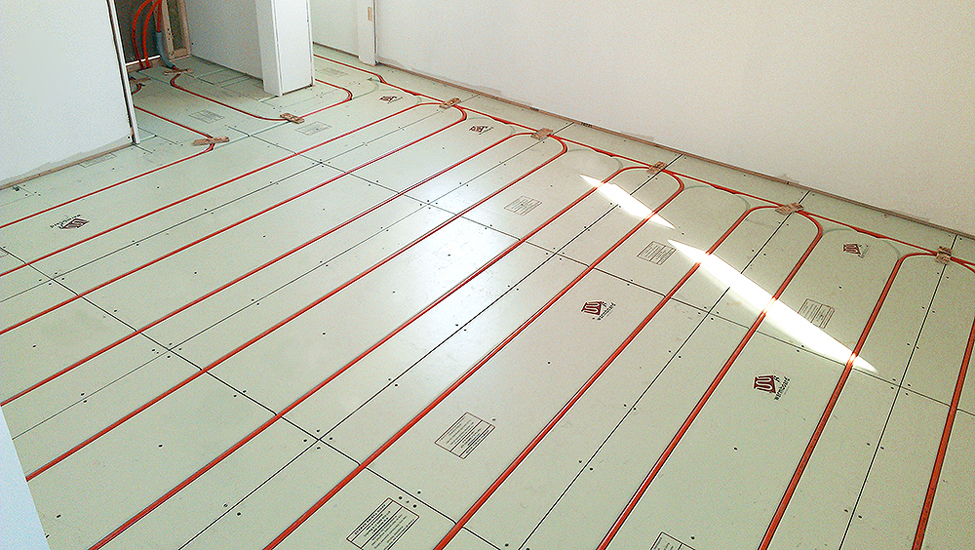

(above), a tongue-and-groove paneling system made of wood and aluminum, with preset grooves a foot apart for half-inch radiant tubing. It's one of the only ways to keep floor-generated radiant heat alive in your Eichler home once your original bites the dust. Photography: courtesy Warmboard, Inc. |

|

|

|

|

|

|

Radiant heating was one of the most 'futuristic' features of Eichler homes when they were introduced—but, according to reports for years around the Bay, that feature is not aging so well today.

A half-century or more later, many of the Eichlers' original systems, especially those that were made of steel, have been lost to corrosion, have developed leaks, or operate ineffectively for other reasons.

As brand manager for a radiant heating company, Ross McCord is a big fan of the technology, but even he concedes its limitations.

"Some radiant heating methods supply uneven heating surface temperatures—the tubing provides temperature, the space between the tubing the coolest. This 'striping' affects comfort and can risk damaging flooring," McCord said recently. "Additionally, some systems are unable to provide adequate heating for some finish flooring options."

Enter Warmboard, McCord's employer. Invented 25 years ago in Capitola by architect and entrepreneur Terry Alsberg, Warmboard is tongue-and-groove paneling made of wood and aluminum, with preset grooves a foot apart for half-inch radiant tubing. It is a product uniquely adaptable to failed radiant systems. The company is also the latest addition to the Eichler Network's roster of Preferred Service Companies.

"For those in Eichler homes, Warmboard is an ideal option," promises McCord. "Homeowners are able to upgrade their high-mass radiant system with a modern solution with minimal impact on the design of the home."

Now based in Aptos, Warmboard has provided more than 25 million square feet of radiant panels for structures worldwide and is the leader of the field here in North America. It is also a viable energy-efficient alternative for some of the first mass-produced homes to use radiant—built by Joe Eichler.

Knowing well the enjoyment radiant heating brings, some Eichler owners over the years have been known to replace their defunct systems with new ones—re-grooving the concrete slab and laying down new Pex tubing in the grooves. The end result may be wonderful, but the installation process is quite challenging, requiring the family to move out of the home, up to three months, while the messy process is completed.

"Radiant heating has numerous benefits, comfort and health [being] the primary ones," said McCord. "Radiant floors spread heat out evenly across an entire area. This is superior to forced air, which loudly blasts overheated air into a room—air which then collects at the ceiling until it dissipates and the system kicks on again.

"Baseboard heat works well, but inhibits where you can place furniture and, the farther away you are, the less comfortable you become. Radiant is about 25-30 percent more energy efficient than forced air, so homeowners can generally see a significant savings on their annual energy usage."

Warmboard brings the opportunity to start over with new tubes inset into the paneling. Their original 'S' model is generally used in new construction, while a newer 'R' model is for remodels. The panels are screwed into the concrete slab or any subflooring in the structure.