Six Myths of Eichler Radiant Heating

Radiant heating systems are nothing new; after all, the Romans used them 2000 years ago. Today, in their evolved and much-improved form, these systems are popular among contemporary architects, especially on high-end and avant-garde projects. Many installations throughout the world have been operating continuously, and successfully, since before the first Eichlers were built. Closer to home, radiant heating continues to bring both pleasure and frustration to Eichler homeowners.

Radiant heating systems are nothing new; after all, the Romans used them 2000 years ago. Today, in their evolved and much-improved form, these systems are popular among contemporary architects, especially on high-end and avant-garde projects. Many installations throughout the world have been operating continuously, and successfully, since before the first Eichlers were built. Closer to home, radiant heating continues to bring both pleasure and frustration to Eichler homeowners.

For the Eichlers' original heat installations, this method of heating falls into a general category called hydronic heating. Simply, it uses water to transfer heat from a central source (usually a boiler) to a remote heating output. For Eichler applications, hydronic tubing is imbedded in the cement slab, but other residential applications include radiators, forced fan convectors, and baseboard convectors.

While not terribly complicated, especially in the single-family home application, they are somewhat special, and it is important to have at least a basic understanding of how these systems operate and recognize small problems before they become big, costly ones.

Here are some of the most common misconceptions—what we call the myths of radiant heating—which Eichler owners continue to pass on from neighbor to neighbor.

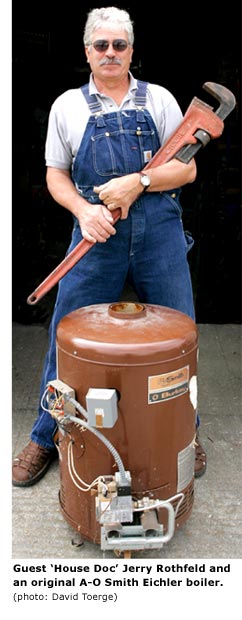

Myth #1: My original boiler is still running problem free. There's no need to replace it until it breaks down.

Don't believe it. There's no question that the original Eichler boilers have been remarkably durable, but they're not problem-free—at least not beyond the surface. Some lucky folks with well-maintained boilers still have all the original parts in place, but these peripheral parts (the circulating pump, gas valve, expansion tank, fill valve, and controls) just simply wear out and need to be replaced. As the pump gets weaker, its decline leads to poor performance - certain areas of the house may stop heating, and the boiler can take many more hours to raise the house temperature.

Replacing these peripheral parts individually on numerous service calls is very costly, and can be terribly untimely. Some parts, such as the gas valve, cannot be used when a new boiler is eventually installed, and others will have to be moved to accommodate the new installation. Installers will seldom give credit for work performed in the past, or extend their warranty to those parts already replaced.

All this time the whole system is firing away very nicely.

Does high fuel cost and terrible pollution qualify as a problem? Most original Eichler boilers are over 40 years old, and grossly inefficient when compared to contemporary replacement models.

The original Eichler boilers simply cannot last forever. Will yours go out on Monday morning in the middle of July—or the day before Christmas?

Myth #2: When it's time to buy a boiler, the higher the efficiency, the better the boiler.

Not necessarily true. A modern atmospheric, or naturally drafted, boiler can reach 85 percent efficiency, which is an upgrade of 20 percent or more over most of the original boilers presently in Eichlers.

High-efficiency sealed-combustion boilers reach the mid-90s, and sometimes even the high 90s, in efficiency. They typically have higher retail prices, and require special installation procedures that can add considerably to the final price. Servicing requires special training and expensive test equipment.

Some high-efficiency products have a better service record than others, but they all have moving parts and special electronic controls that are expensive and unique to the brand. While manufacturers may offer a ten-year (or longer) warranty on leaks from the boiler itself, controls are generally limited to one-year coverage.

These models also make more noise than a conventional boiler, some brands more than others. Still, there are many situations when a high-efficiency boiler is appropriate and cost-effective; but all factors should be carefully weighed against the additional six to ten percent fuel savings over a new atmospheric boiler

Myth #3: All steel-pipe radiant heat systems will eventually rust out.

Not always the case. A pipe in a 'closed-loop' system does not deteriorate in the same way as the drinking water piping. It does not consume water; and after an initial filling, goes oxygen dead after a few days. Hence, there is no corrosion or mineral build-up, regardless of water quality.

Steel pipes do not rust from the inside if the system is leak free and well maintained. That's a big 'if.' Steel pipes are very unforgiving, and even a minor leak left unattended can cause irreversible damage by allowing oxygen to be drawn in to the closed loop that can corrode the system. Wet conditions in the slab from poor drainage, roof leaks, or plumbing leaks can do serious damage to the outside of the steel pipes.