Your Eichler's Mahogany Paneling

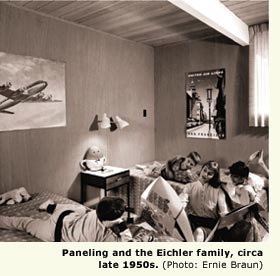

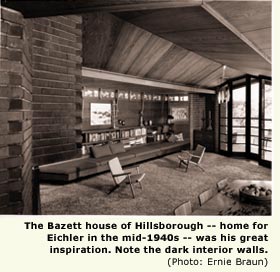

Nothing says "it's an Eichler original!" like an Eichler home with its interior walls dressed in deep-toned paneling. While this feature may not be quite as prominent as the Eichler's walls of glass, its atrium, or even its low-sloped roof, it is nonetheless quintessential Eichler.

But why did Joe Eichler choose wood paneling for his interior walls? Was it a design decision? An aesthetic one? A structural consideration? Or was it all about cost? And just as important, what are Eichler homeowners' choices today, as they look to restore and refresh their original Eichler interiors?

Philippine mahogany, also known generically as 'lauan' (among other names, depending on its country of origin), is a hard wood that originates from several countries in southeast Asia. It is not derived from one particular tree, but from a family of trees. The commercial product originally used by Eichler is still widely available, though some claim that it is of lower quality today because it now comes from Malaysia, rather than the Philippines.

The product consists of plywood with a thin layer of lauan veneer covering it. The sheets are inexpensive (available today from $10 to 20 per four-foot by eight-foot sheets), thin, relatively lightweight, and easy to use. Lauan can be found at many Bay Area lumber outlets, including Home Depot, Southern Lumber (San Jose), Northern Hardwood (Santa Clara), Jordan International Company (Belmont), MacBeath Hardwood Company (Berkeley and San Francisco), and Western Plywood (San Francisco).

Bill Willis worked for Eichler Homes for 25 years, first as a part of Eichler's construction crew and later as foreman, beginning in the early 1950s. Willis's reflections provide us a window into the past, back to the days when Eichler's building machine was in its prime and paneling was his standard.

Eichler's decision to use interior paneling, Willis points out, was based on design and aesthetics, and was not about cost. "Joe Eichler really loved that wood paneling, and he would have never stopped using it if he hadn't been forced to by changes to the building code [by the mid 1960s]," says Willis. "He had a way with things—and if he liked something, he would not change it, no matter what."

Eichler employed a separate crew that specialized in staining the interior paneling, and Willis recalls that they used the same color mix throughout Eichler's building career.

Eichler's process of developing and finalizing designs and choosing materials had more to do with creativity and aesthetics than one might imagine, especially when considering that Eichler was geared almost exclusively to mass-producing 'affordable' housing. "Eichler got his ideas from many sources," says Willis, "but his architects—especially Claude Oakland—played a key role. Joe got more ideas from Oakland than just about anyone else."

In fact, Eichler met with his architects for several hours each week, recalls Willis, and during those meetings they would review plans and brainstorm ways to improve the new models. Many unique ideas rose out of those sessions, including Eichler's suggestion of extending the exterior grooved siding into the interior of the home. The architects especially liked this aesthetic enhancement, remembers Willis, "and they advised Eichler which models would benefit the most from this technique."

Eichler also preferred interior doors faced with the same mahogany paneling, and would not tolerate the use of mass-produced, pre-hung doors. "I tried for years to get Joe to switch to pre-hung doors," Willis admits, "which were about one-tenth the cost, but he would not hear of it."

According to Jonathan Cooke, an Eichler owner and Eichler-focused general contractor with Renaissance Man Construction, many tract builders of the 1950s and early '60s used wood paneling merely because it was cost effective. Most of them, he says, used an inferior grade of wood paneling, which caused, in part, changes in the building codes to their current requirements of drywall or similar products. "At that time, drywall finishing technology had not been refined," points out Cooke. "It was often more expensive to finish drywall than use some wood paneling products that were available at the time."